- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2026-01-30 Origin: Site

You follow a precise process when manufacturing welded machined components. The main stages include material selection, machining, welding, inspection, and finishing. Each step uses advanced equipment to ensure accuracy and quality. Jiangsu VY Precision Machinery offers large-scale CNC machining for metal structures and specializes in energy equipment production. The typical manufacturing processes include preparation, cutting and shaping, forming and bending, and assembly. These stages help you achieve reliable components.

| Stage | Description |

|---|---|

| Preparation | Clean, deburr, and cut materials to size for weld quality. |

| Cutting and Shaping | Transform raw materials using shearing, sawing, and laser cutting for precision. |

| Forming and Bending | Shape metal using bending and stamping. |

| Assembly and Joining | Join components with welding, bolting, and riveting, focusing on welding. |

For advanced manufacturing solutions, Jiangsu VY Precision Machinery provides expertise and modern facilities.

Choose the right materials for welded components to ensure strength and durability. Consider properties like corrosion resistance and mechanical strength.

Follow a precise preparation process before machining. Clean and organize materials to achieve accurate results during manufacturing.

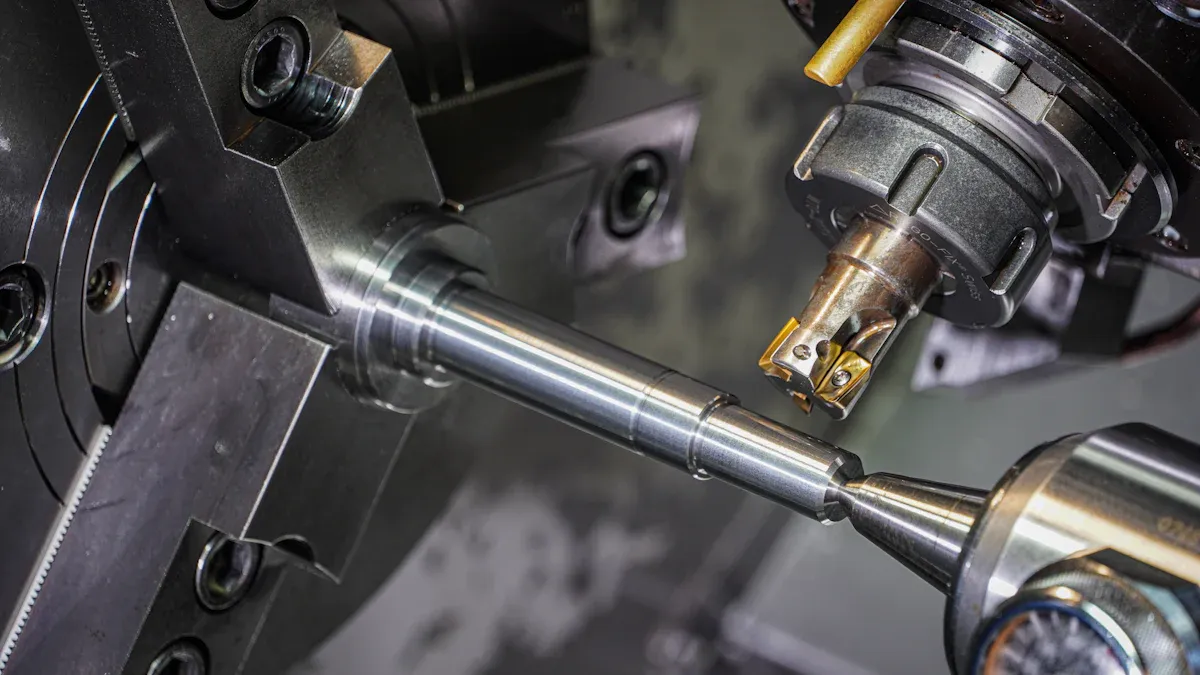

Use CNC machining for high precision and repeatability. This technology helps reduce errors and allows for complex shapes in your components.

Perform thorough inspections before and after welding. Use visual checks and non-destructive testing to ensure quality and identify defects early.

Select appropriate surface finishing techniques to enhance appearance and protect against corrosion. Options include polishing, plating, and powder coating.

You start the manufacturing process by selecting the right materials for welded machined components. The energy equipment industry uses a wide range of metals. You often see these materials in machining:

Steel: Carbon steel, stainless steel

Aluminum: Aluminum alloys, aluminum-magnesium alloys

Copper and copper alloys: Pure copper, bronze, brass

Nickel and nickel alloys: Nickel-based alloys

Titanium: Titanium alloys

Cast iron: Gray cast iron, ductile cast iron

Other metals and alloys: Magnesium alloys, refractory metals like tungsten and molybdenum

You must consider several factors when choosing materials for your components. The table below shows the main criteria you use to ensure durability and performance:

| Criteria | Description |

|---|---|

| Material Properties | Different metals (steel, aluminum, stainless steel) have unique physical and chemical properties, requiring careful selection. |

| Surface Preparation | Cleaning surfaces to remove contaminants is crucial for ensuring strong weld connections. |

| Filler Material Matching | Selecting the appropriate filler material enhances connection strength and reduces defects. |

| Environmental Conditions | Adjustments may be necessary based on environmental factors, such as humidity, to maintain weld quality. |

You see the importance of machining at this stage. The right material choice supports the entire manufacturing process and helps you achieve reliable results.

You prepare raw materials before machining and welding by following a series of steps. These steps help you maintain quality and efficiency in your manufacturing processes:

Select the correct steel grades and types for your project.

Order materials according to your specifications.

Inspect incoming materials to ensure they meet quality standards.

Organize materials for a smooth workflow.

Measure and mark materials for precise machining.

You must focus on the importance of machining during preparation. Clean, marked, and organized materials allow you to achieve accurate results in every process. Jiangsu VY Precision Machinery uses advanced equipment and strict preparation methods to support high-quality welded machined components.

Jiangsu VY Precision Machinery Co.,Ltd. operates in the Honglan Industrial Concentration Area of Lishui District, Nanjing. You benefit from a factory that covers 35,000 square meters, with a floorage of 28,000 square meters. The company has a registered capital of 20 million yuan and was established in 2009. You rely on advanced imported equipment for numerical control cutting, sheet metal processing, welding, and machining. The company specializes in the design, manufacturing, and services of energy equipment. You gain access to large-scale precision CNC machining capabilities for metal structures.

You use CNC machining to shape and refine welded machined components. CNC machining processes allow you to achieve high accuracy and repeatability. You program machines to cut, drill, and mill metal parts according to your specifications. You select the right machining processes based on the material and design. You monitor each step to ensure the finished component meets your requirements. You rely on advanced CNC machining to produce complex geometries and tight fits. You see the benefits of automated machining in reducing errors and improving efficiency.

Tip: You should always check the setup before starting machining. This helps you avoid mistakes and ensures consistent results.

You focus on tolerances to guarantee the quality of welded machined components. Tolerances define the allowable variation in dimensions. You follow standards like ISO 13920:2023 for welded constructions. You use fixtures to hold parts in place and achieve tighter tolerances. You often work with a common welding tolerance of 1/16”. You know that tighter tolerances may increase costs but improve performance. In precision machining, you can reach tolerances of ±0.01 mm or better. This level of control is essential for industries such as automotive, aerospace, and medical devices.

| Tolerance Type | Description |

|---|---|

| General Tolerances | ISO 13920:2023 outlines tolerances for lengths, angles, shape, and position |

Common welding tolerance: 1/16”

Tighter tolerances can be achieved with fixtures

You check tolerances at every stage of machining. You measure parts using calipers, micrometers, and coordinate measuring machines. You adjust machining processes to maintain the required tolerances. You understand that precise tolerances lead to reliable and high-performing components.

You need to clean machined components before welding to achieve strong joints and prevent defects. Machining leaves behind oils, lubricants, and oxides that can cause problems during welding. You use several cleaning methods to remove these contaminants:

Abrasive pens and fine wire brushes help you reach edges and joints.

Rinsing with a neutral pH solution neutralizes acidic residues.

Drying with a heat gun or microfiber cloth ensures no moisture remains.

Handling cleaned materials with clean gloves prevents recontamination.

You can also use advanced cleaning techniques for thorough results:

Laser cleaning removes contaminants without touching the surface.

Chemical cleaning dissolves surface residues using alkaline or acidic solutions.

Mechanical abrasion uses wire brushes to eliminate oxides.

Solvent degreasing removes oils and grease.

Plasma cleaning uses ionized gas to clear away surface particles.

Regular inspection under proper lighting helps you confirm that no residue remains. Oxides and contamination from machining can lead to weld defects, so you must pay attention to every detail. You prepare each component carefully to support high-quality welding.

You perform quality inspection before welding to ensure component integrity. You check if the weld area is adequate in size and free of slag. You look for signs of undercut, incomplete fusion, or porosity. You use both visual and advanced testing methods to verify weld readiness.

| Assessment Level | Description |

|---|---|

| Level 1 | Visual inspection of the welded joint with unaided eyes or a magnifying glass. |

| Level 2 | Non-destructive testing (NDT) methods like ultrasonic testing or radiography to find hidden flaws. |

| Level 3 | Destructive testing methods where part of the weld is cut out and tested in a lab. |

You rely on non-destructive testing for most products. Ultrasonic testing uses sound waves to find internal flaws. Radiography uses X-rays or gamma rays to inspect welds. Magnetic particle testing detects surface and near-surface defects. Liquid penetrant testing reveals surface-breaking flaws with dye.

Measuring weld bead dimensions and penetration depth helps you confirm that the weld meets design specifications. You ensure that every step, from machining to inspection, supports the overall quality of the finished component. Jiangsu VY Precision Machinery uses advanced equipment and strict inspection standards to deliver reliable results.

You need to secure each part before welding to achieve precise results. Fixturing holds your machined parts in the correct position and orientation. This step is essential for both manual and robotic welding. You can choose from several types of fixtures:

Plate fixtures

Angle-plate fixtures

Vise-jaw fixtures

Indexing fixtures

Multi-part or multi-station fixtures

Fixtures play a key role in mass production and when you work with complex shapes. You use positive stops and strong clamps on datum surfaces. You design clamps to avoid tool interference. You make part orientation clear and often add ergonomic handles or air-cylinders for high-volume cells. You ensure enough space for tool paths, chips, and coolant. You may use asymmetric cavities or pins to prevent misloads. For automated or robotic welding, you add sensors or mechanical interlocks. You label clamps and provide visual instructions at the cell. You simulate the loading and clamping sequence to catch problems before production.

Fixturing increases the stiffness of flexible parts. This helps you maintain quality during the welding manufacturing process. You rely on proper fixturing to reduce distortion and keep your welded machined components accurate.

You select the right welding technique based on your project needs. The three main methods are MIG, TIG, and arc welding. Each method has unique features. You often use robotic welding for high-volume or complex jobs. Robots improve consistency and speed in your manufacturing processes.

| Feature | MIG Welding | TIG Welding |

|---|---|---|

| Weld strength | Weaker than TIG due to wider arc | Stronger due to narrow arc |

| Weld speed | Faster, suitable for thicker metals | Slower, more time-consuming |

| Welding gas | Mixture of argon and CO2 | 100% argon |

| Weld aesthetics | Can be good but less consistent | Professional and clean appearance |

| Operator skill | Less skill required | Requires more skill and control |

You use MIG welding when you need speed and efficiency. This method works well for thicker metals and large production runs. Robotic welding systems often use MIG for repetitive tasks. You choose TIG welding for projects that demand high weld quality and a clean finish. TIG is slower and needs more skill, but it produces strong, precise welds. You use arc welding for basic jobs or when you need a simple setup. Robotic welding can handle all three methods, depending on your requirements.

You program robots to follow exact paths. This reduces human error and increases repeatability. Robotic welding ensures each weld meets your standards. You see fewer defects and higher productivity in your manufacturing.

You must check the weld profile right after welding. The weld profile includes the shape, size, and smoothness of the weld bead. You measure bead size and position to ensure accuracy. For tack welding, you keep bead size within ±0.635 inches. For positional accuracy, you aim for ±0.010 inches. You follow ISO 2768 for general tolerances. For more precise work, you mark tolerances on technical drawings using ISO 286.

Welding creates heat that can cause parts to expand and contract. This may lead to distortion. For short welds or well-fixtured parts under 100 mm, you can achieve tolerances of ±0.5 mm to ±1.0 mm. For longer welds or complex assemblies, you may need to allow ±1.0 mm to ±2.0 mm.

You perform immediate inspection to catch any issues early. Your inspection methods include:

| Inspection Method | Description |

|---|---|

| Visual Inspection | The first step in identifying surface issues like irregularities or cracks. |

| Radiography | Used for detecting internal defects through X-ray imaging. |

| Magnetic Particle Testing | Identifies surface and near-surface discontinuities in ferromagnetic materials. |

| Ultrasonic Testing | Employs high-frequency sound waves to detect internal flaws. |

You also use liquid penetrant and magnetic particle examinations. You combine visual checks with advanced non-destructive tests. This ensures your welds meet quality standards and are structurally sound.

You rely on the welding manufacturing process to deliver strong, accurate welded machined components. Robotic welding, precise fixturing, and immediate inspection help you maintain high quality in every production run. If you want reliable results and advanced manufacturing, Jiangsu VY Precision Machinery offers expertise and modern facilities.

You often need to perform machining after welding to achieve the final dimensions and tolerances required for welded machined components. Welding can change the shape of your parts. Heat from welding causes expansion and contraction. This can lead to distortion or slight shifts in the metal. You must correct these changes to ensure your components fit and function as designed.

You use several machining processes after welding. These processes help you remove excess material, smooth out weld beads, and create precise holes or threads. Common machining after welding steps include:

Grinding weld beads and blending seams for a smooth surface

Milling surfaces to achieve flatness and exact thickness

Drilling and tapping holes for fasteners or assembly

Sand blasting or shot blasting to clean and prepare surfaces

Applying heat treatment for stress relief or normalizing

You may face challenges during machining after welding. The table below shows some common issues and their explanations:

| Challenge | Explanation |

|---|---|

| Material Distortion | Expansion and contraction during welding can change the shape of your parts. |

| Changes in Mechanical Properties | The heat-affected zone may have different strength or hardness, which affects machining accuracy. |

| Equipment Variability | Differences in machines or tools can cause inconsistent results in your production. |

You must check each part carefully during machining after welding. You use measuring tools like calipers and micrometers to confirm that you meet the required tolerances. You adjust your machining process if you see any deviation. This attention to detail helps you maintain high quality in your manufacturing.

Jiangsu VY Precision Machinery uses advanced CNC machining equipment to handle post-weld machining with precision. You can trust their expertise for reliable results in your manufacturing processes. Learn more about their capabilities at https://www.jsvypm.com/.

You need to finish the surface of welded machined components to improve appearance, durability, and performance. Surface finishing removes any remaining imperfections from machining after welding. It also prepares your components for protective coatings or final assembly.

You can choose from several effective surface finishing techniques:

Laser treatments give you high control over the surface finish. You can use them to prepare surfaces for coatings or bonding.

Plasma treatments offer a cost-effective way to etch or modify the chemical composition of your parts.

Brushing removes burrs and cleans the surface without changing the dimensions.

Plating adds a layer of metal for corrosion resistance and allows you to control thickness.

Polishing makes the surface shiny and increases resistance to corrosion.

Powder coating creates a strong barrier against corrosion and comes in many colors.

Sandblasting quickly removes contaminants and smooths the surface.

The table below summarizes the advantages and applications of these techniques:

| Technique | Advantages | Applications |

|---|---|---|

| Laser Treatments | High control, removes contaminants, modifies roughness | Prepares for coatings or bonding |

| Plasma Treatments | Cost-effective, etches, modifies chemical composition | Etching, chemical modification |

| Brushing | Removes burrs, cleans, maintains dimensions | Maintains tolerances in machined parts |

| Plating | Corrosion resistance, controls thickness | Enhances durability of components |

| Polishing | Improves appearance, increases corrosion resistance | Final finishing for reflective surfaces |

| Powder Coating | Corrosion barrier, color options | Common for metal components |

| Sandblasting | Removes contaminants, smooths surfaces | Cleans and prepares surfaces |

You select the right finishing technique based on your production needs and the function of your components. You may combine several methods to achieve the best results. Surface finishing is a key step in the manufacturing of welded machined components. It ensures your products look good, last longer, and perform well in their applications.

Jiangsu VY Precision Machinery offers a full range of surface finishing options as part of their manufacturing services. You can rely on their experience and advanced equipment for high-quality welded machined components.

You need to confirm that your welded machined components meet all specifications before you finish the manufacturing process. You check dimensional accuracy to ensure each part fits and functions as designed. You use precise measuring tools like calipers, micrometers, and coordinate measuring machines. These tools help you verify that every surface and hole matches your drawings. You focus on dimensional accuracy at this stage because even small errors can affect the performance of high-quality components.

You also perform non-destructive testing to check for hidden flaws. This step helps you maintain quality without damaging your parts. You use several common methods for final inspection:

| Testing Method | Description |

|---|---|

| Visual Inspection | Basic method to assess surface conditions and detect visible defects. |

| Liquid Penetrant Testing | Detects surface-breaking defects by applying a penetrant and examining the surface for indications. |

| Magnetic Particle Inspection | Identifies surface and near-surface defects in ferromagnetic materials using magnetic fields. |

| Ultrasonic Testing | Uses high-frequency sound waves to detect internal flaws and measure material thickness. |

| Radiographic Testing | Employs X-rays to visualize internal structures and identify defects within materials. |

Magnetic particle testing works well for welding inspections, especially for parts under mechanical stress.

Ultrasonic testing gives you precise results for flaw detection and material measurement.

Radiographic testing uses X-rays to reveal internal structures and defects.

You rely on these inspection methods to ensure your manufacturing process produces high-quality components with the required dimensional accuracy.

You apply surface treatments to protect your welded machined components and improve their appearance. You may use powder coating, plating, or painting to prevent corrosion and extend the life of your products. You select the right treatment based on the application and environment. Surface treatment also helps you meet industry standards for durability and finish.

You package each part carefully to prevent damage during shipping and storage. You use foam, plastic wrap, or custom crates to keep your components safe. You label each package with part numbers and handling instructions. This step ensures your products arrive in perfect condition and are ready for use.

You complete the manufacturing process by combining careful inspection, effective surface treatment, and secure packaging. You achieve reliable results and deliver high-quality components to your customers. If you want advanced manufacturing and strict quality control, Jiangsu VY Precision Machinery offers modern facilities and expert support.

You follow a clear process to manufacture welded machined components. Each stage, from material selection to final inspection, plays a key role in quality. Advanced equipment and automation help you achieve precision and repeatability. You benefit from thorough process control, which prevents defects and ensures reliable results. Jiangsu VY Precision Machinery uses modern CNC machining and strict quality systems to deliver high-quality products. You should value process control and precision when choosing a manufacturer for your needs.

Jiangsu VY Precision Machinery offers expertise and advanced facilities for your manufacturing projects.

You can use steel, aluminum, copper alloys, nickel alloys, titanium, and cast iron. Each material offers unique properties for strength, durability, and corrosion resistance. Jiangsu VY Precision Machinery helps you select the best option for your project.

You inspect each weld visually and with non-destructive testing. You use ultrasonic, radiographic, and magnetic particle methods. These checks help you find defects early and maintain high standards.

Tip: Always clean and prepare surfaces before welding for stronger joints.

CNC machining gives you precise control over dimensions and tolerances. You achieve repeatable results and complex shapes. This process reduces errors and improves the quality of your finished components.

Yes, you can rely on Jiangsu VY Precision Machinery for large-scale CNC machining and welding. The company uses advanced equipment and offers complete solutions for energy equipment.