- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2026-01-30 Origin: Site

You need to match tower mechanical internals to your process needs if you want to achieve true operational reliability. The right internals improve process performance and help you resist fouling. You also make maintenance easier when you select carefully. For expert guidance, you can trust Jiangsu VY Precision Machinery to support your decision. Focus on clear, actionable criteria as you move forward.

Understand your process requirements before selecting tower mechanical internals. Consider factors like temperature, pressure, and fluid characteristics.

Choose internals that resist fouling and corrosion. This choice improves performance and reduces maintenance needs.

Define your performance goals clearly. Set targets for capacity and efficiency to guide your selection process.

Prioritize easy cleaning and accessibility in your internals. This approach helps maintain high performance and extends equipment life.

Consult with experts like Jiangsu VY Precision Machinery for tailored advice. Their experience can help you avoid costly mistakes.

Evaluate the trade-offs between cost and performance. Consider the total cost of ownership, including maintenance and energy use.

Regularly inspect and maintain your tower internals. This practice prevents fouling and ensures reliable operation.

Stay flexible in your design choices. Select internals that can adapt to changing process conditions for long-term success.

Selecting the right tower mechanical internals starts with a clear understanding of your process requirements. You need to consider the operating environment, performance targets, and maintenance expectations. Consulting with specialists helps you address unique challenges and avoid costly mistakes. You should always evaluate fouling potential and fluid properties before making a final decision.

You must assess the temperature and pressure ranges your equipment will face. These factors influence the durability and performance of tower mechanical internals. High temperatures can cause cracking or deterioration of tower shells. Pressure changes may reduce the lifespan of internal components. The table below shows how these variables impact your system:

| Factor | Impact on Performance and Longevity |

|---|---|

| Temperature Variations | Can lead to cracking and deterioration of cooling tower shells, affecting structural integrity over time. |

| Pressure Variations | Influences the long-term performance and can exacerbate deterioration phenomena. |

You should match the specification of your internals to withstand these stresses. Proper design and material selection ensure reliable operation in harsh environments.

The fluids moving through your tower affect fouling and corrosion rates. You need to analyze the chemical composition, purity, and flow patterns. The table below outlines key fluid characteristics and their effects:

| Fluid Characteristic | Effect on Fouling/Corrosion |

|---|---|

| Concentration of Cl, Va, Mo, O2 | Significant effect on fouling rate |

| Surface temperature | Influences fouling resistance and corrosion rates |

| Purity of the fluid | Affects the likelihood of fouling and corrosion |

| Surface roughness | Impacts fouling deposit formation |

| Geometry of heat exchanger | Affects fluid flow and fouling resistance |

| Uniform fluid flow | Reduces fouling deposit significantly |

You should specify internals that resist fouling and corrosion. For example, high temperatures increase corrosion rates and can reduce the effectiveness of antifoulants. Uniform fluid flow helps minimize fouling deposits.

You must define the required capacity for your tower. The choice between natural draft and mechanical draft towers depends on your capacity needs. Natural draft towers use air buoyancy, while mechanical draft towers use fans for airflow control. Airflow optimization is essential for performance. You need to ensure strategic placement of components and proper water distribution. Uneven distribution can lower efficiency, so precise nozzle placement and fill material coverage are critical.

You should set clear efficiency targets for your process. In distillation and fractionation columns, modern internals focus on reducing pressure drop, maximizing capacity, and minimizing fouling. These improvements boost equipment efficiency and reduce operational costs. The table below highlights how design factors impact production efficiency:

| Design Factor | Impact on Production Efficiency |

|---|---|

| Feed inlet distributors | ±15% separation consistency |

| Packing support grid design | 22% reduction in weepage losses |

| Chimney tray gas velocity | 19% decrease in entrainment |

Optimized packings can reduce reboiler energy use by up to 18%. Advanced absorption towers achieve solvent utilization rates as high as 99.5%. Computational fluid dynamics modeling can further enhance column stability.

You need to consider how easy it is to clean your tower internals. Common maintenance challenges include scale buildup, corrosion, biological growth, and leaks. You should select designs that allow for straightforward cleaning and minimize downtime. Regular cleaning extends the life of your equipment and maintains high performance.

You should ensure that your tower internals are accessible for inspection and repair. Good specification and design make it easier to reach critical components. This reduces maintenance time and helps you quickly address any issues that arise.

Tip: Always consult with experienced manufacturers like Jiangsu VY Precision Machinery when specifying tower mechanical internals. Their expertise in design and manufacturing can help you meet your process requirements and improve reliability.

You need to understand the main types of tower mechanical internals before you make a selection. Each type serves a specific purpose and fits different process requirements. The table below compares common column types and their internals:

| Column Type | Internals Used | Mass Transfer Efficiency | Cleaning Ease | Mechanical Complexity |

|---|---|---|---|---|

| Spray Column | None (open) | Low | High | Very Low |

| Packed Column | Random/structured packing | Medium–High | Medium | Low |

| Tray Column | Sieve or valve trays | Medium | Medium | Medium |

| Pulsed Column | Trays + pulsation unit | High | Low | High |

| RDC Column | Rotating discs/stators | Very High | Low | Very High |

Trays create stages for gas and liquid to mix inside the tower. You often see three main types: sieve, valve, and bubble cap trays.

Sieve trays have holes that let vapor pass through the liquid. They work well for many standard applications.

Valve trays use movable valves to adjust vapor flow. You can use them for a wider range of flow rates.

Bubble cap trays have caps and slots that force vapor to bubble through the liquid. They handle low flow rates and are good for tough separations.

You should consider the process conditions and maintenance needs when choosing a tray type.

You need to focus on the right tower tray for your process. Trays work best for high-capacity operations and tough separations. They are easier to clean and inspect than other internals. You should use proper tray selection to match your flow rates and separation goals. Trays are common in petrochemical plants and large-scale operations.

Tip: For expert advice on tray selection and manufacturing, you can consult Jiangsu VY Precision Machinery.

Packings provide a large surface area for gas and liquid to contact. You can choose between structured and random packings.

Structured packings have a regular, organized shape. They offer higher efficiency and lower pressure drop than random packings. Random packings use loose pieces, like rings or saddles, that fill the column.

Structured packings reduce energy use and improve separation. They also resist fouling and corrosion better than random packings.

You can select packings made from metal, ceramic, or plastic. Metal packings handle high temperatures and strong chemicals. Ceramic packings resist corrosion and thermal shock. Plastic packings work well for low-temperature or non-corrosive processes.

Grids and supports hold the internals in place and help distribute fluids evenly.

Support grids provide stability and prevent the internals from moving during operation. They also stop media from bypassing along the vessel wall. You should choose a grid design that matches your packing type and process loads.

Distribution systems ensure that liquid and vapor spread evenly across the tower. Good distribution improves mass transfer and reduces fouling. You need to check that your supports and distributors are easy to install and maintain.

Note: Proper grids and supports are essential for tower safety and performance. Jiangsu VY Precision Machinery offers custom solutions for your process needs.

Choosing the right tower mechanical internals for your application means understanding how each process challenge affects performance. You need to match internals to the specific demands of fouling services, cooling, and separation. This approach helps you achieve reliability, efficiency, and long equipment life.

Fouling services create some of the toughest conditions for tower mechanical internals. You face problems like polymerizing fluids and particulates that can block flow paths, reduce efficiency, and increase maintenance.

Polymerizing fluids can quickly coat surfaces and clog internals. You need to validate your column design against actual process conditions. This step prevents maldistribution and low efficiency. Specialized internals help you resist fouling and corrosion. The table below shows important design considerations for polymerizing fluid services:

| Design Consideration | Description |

|---|---|

| Validate Column Design Against Actual Process Conditions | Ensure that the column design is appropriate for current operating conditions to avoid issues like maldistribution and low efficiency. |

| Evaluate Fouling-Resistant Solutions | Implement specialized internals to combat fouling and corrosion, which are critical in polymerizing fluid services. |

You should select internals that allow easy cleaning and quick replacement. Dual flow trays or grid packing offer high reliability in severe fouling services. The table below matches tray types to fouling severity:

| Fouling Severity | Recommended Tray Type |

|---|---|

| Light fouling | Fixed valve trays or large-hole sieve trays |

| Moderate fouling | Fixed valve trays for efficiency and resistance |

| Severe fouling/polymerization | Dual flow trays or grid packing for reliability |

Tip: Always review your process data before finalizing internals for fouling services. This step ensures you get the best performance and lowest downtime.

Particulates in process streams can block nozzles, reduce heat transfer, and increase energy costs. You need to consider how solids affect your system. The table below highlights the main impacts:

| Impact of Particulates | Description |

|---|---|

| Heat Transfer Efficiency | Suspended solids reduce efficiency, requiring higher water flow to maintain heat removal rates. |

| Energy Costs | Increased flow leads to higher energy costs for pumping. |

| Clogging of Nozzles | Small orifices in nozzles can become blocked, disrupting water distribution. |

You may see blocked flow paths that force gas through only part of the scrubbing bed. Uniformity in the packed bed is crucial. Blockages can lead to gas bypassing cleaning processes. Clogging of packing elements can result in ineffective scrubbing.

Automatic filtration can reduce operating and labor costs.

It helps you comply with regulations on water use and disposal.

Self-correcting filters can manage upsets effectively.

You should choose tower mechanical internals that resist clogging and allow for easy cleaning. This approach keeps your fouling services running smoothly.

Cooling tower internals play a key role in heat removal and system reliability. You must focus on cooling efficiency and material selection to get the best results from your cooling tower.

You need to size your cooling tower correctly to meet your cooling needs. An undersized cooling tower can lead to insufficient cooling, risking equipment damage and downtime. Capacity must match your process requirements to prevent costly repairs and productivity losses. Application suitability ensures your cooling tower works well for your industry.

Key factors for cooling tower design include:

Size: The cooling tower must be large enough for your application.

Capacity: Adequate capacity prevents operational problems.

Application Suitability: The cooling tower must fit your process.

Other important points for cooling tower internals:

Size: Choose internals that match the cooling tower size.

Location: Place the cooling tower for good airflow and minimal debris.

Efficiency: Select internals that maximize cooling efficiency.

Design Considerations: Pay attention to pipe sizing, header sizing, and pump sizing.

You should always check that your cooling tower internals support even water distribution and efficient air movement. This step boosts cooling and reduces fouling services.

Material selection for cooling tower internals affects corrosion resistance and lifespan. You need to match materials to your process water and treatment chemicals. The table below shows key factors:

| Factor | Evidence |

|---|---|

| Material Compatibility | All spray system components must demonstrate proven material compatibility with process water and treatment chemicals. |

| Fasteners and Anchors | Using SS 316 fasteners is essential to prevent premature structural failure due to corrosion. |

| Water Chemistry | Aggressive water chemistry requires advanced materials like SS 316 or specialized polymer coatings to combat rapid corrosion. |

| Operating Temperature | High temperatures necessitate the use of heat-resistant alloys and thermal plastics to maintain structural integrity. |

| Air Quality | Full SS 316 construction is often required in industrial environments to combat atmospheric corrosion. |

You should use SS 316 or advanced polymers for aggressive water or high temperatures. This choice extends the life of your cooling tower and reduces fouling services. For expert advice on cooling tower design and material selection, you can consult Jiangsu VY Precision Machinery.

You need to maximize separation and throughput in high-capacity towers. The right tower mechanical internals help you achieve high purity, low pressure drop, and long equipment life.

You should select internals that provide a large contact surface for vapor and liquid. This design boosts mass transfer and increases production without major changes. The table below highlights the benefits:

| Benefit | Description |

|---|---|

| Maximized Contact Surface | Enhances vapor–liquid interaction for higher purity and consistency. |

| Minimized Pressure Drop | Smart design ensures efficient flow with less resistance, leading to savings. |

| Boosted Efficiency & Throughput | Better mass transfer can increase production capacity without major modifications. |

| Improved Equipment Longevity | Consistent performance reduces wear and extends column life. |

You should use structured packings or high-performance trays for high-capacity applications. These internals help you handle large flows and maintain separation quality.

You need internals that minimize pressure drop and resist fouling services. High-efficiency designs reduce energy use and improve product quality. You should look for internals that allow easy inspection and cleaning. This approach keeps your tower running at peak performance.

Note: Matching tower mechanical internals to your application ensures you get the best results. For custom solutions and expert support, reach out to Jiangsu VY Precision Machinery.

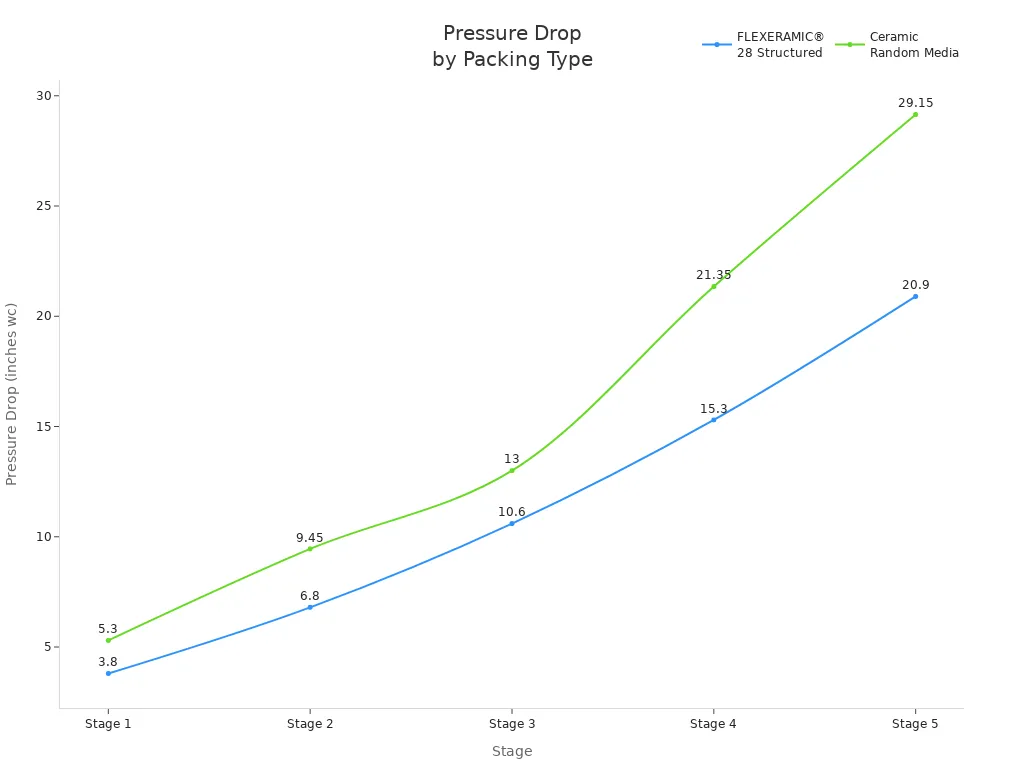

You need to pay close attention to pressure drop when you select tower mechanical internals. Pressure drop measures how much resistance the internals create as fluids move through the tower. Lower pressure drop means your system uses less energy and operates more efficiently. If you choose internals with a high pressure drop, you may face higher energy costs and reduced throughput.

Different types of packings create different pressure drops. The table below shows typical pressure drop ranges for various packing types:

| Type of Packing | Pressure Drop Range (in. water) |

|---|---|

| Low L' and Ga rates | 0.003 – 0.006 |

| High L' (3,500) and Ga (2,000) rates | 0.03 – 0.06 |

You should match the pressure drop to your process needs. For example, structured packing often gives you a lower pressure drop than trays. This feature helps you save energy and maintain stable operation. If your process requires high flow rates, you may need to accept a slightly higher pressure drop to achieve better separation.

Tip: Always balance pressure drop with your efficiency goals. Lower pressure drop can reduce operating costs, but you must ensure your tower still meets your separation requirements.

Fouling can block flow paths and reduce the performance of your tower. You need internals that resist fouling, especially if your process uses fluids with solids or sticky materials. The design and material of the internals play a big role in fouling resistance.

The table below compares fouling resistance features for common tower internals:

| Type of Internal | Characteristics | Fouling Resistance Features |

|---|---|---|

| Trays | Open structure, less prone to plugging | Enhanced outlet weirs, sloped downcomers, large fixed valves |

| Structured Packing | Low pressure drop, smooth surface | Thicker metal sheets, large crimp height, custom distributors |

You should choose trays with open structures if you expect heavy fouling. Features like sloped downcomers and large valves help prevent plugging. Structured packing with smooth surfaces and custom distributors can also reduce fouling. Regular cleaning and inspection keep your tower running well.

Note: Jiangsu VY Precision Machinery offers custom-designed internals with advanced fouling resistance.

You need flexibility in your tower internals if your process conditions change often. Flexible internals let you adjust to different flow rates, temperatures, or product types. Trays with movable valves or adjustable weirs give you more control. Structured packing can handle a wide range of operating conditions with minimal changes.

Flexible designs help you adapt to new products or process upgrades. You can switch between different operating modes without major equipment changes. This feature saves you time and money in the long run.

Choose flexible internals if you expect process changes.

Look for designs that allow easy adjustment and maintenance.

Flexible tower internals help you future-proof your operation. You can respond quickly to market demands and process changes.

When you select tower mechanical internals, you face a key challenge: balancing cost with performance. You want your system to run efficiently, but you also need to control expenses. Making the right choice means understanding how each option affects your budget and your process results.

Cost and performance often pull in different directions. High-performance internals may use advanced materials or complex designs. These features can increase your initial investment. Lower-cost options might save money upfront, but they could lead to higher maintenance or reduced efficiency over time.

Tip: Always consider the total cost of ownership, not just the purchase price. Maintenance, energy use, and downtime all add up.

You can use several strategies to find the best balance:

Optimization frameworks use mathematical models. These models help you weigh material usage, manufacturing costs, and structural performance.

Multi-objective algorithms let you explore different solutions. You can see how changing one factor affects both cost and performance.

Early consideration of manufacturing constraints helps you design internals that are easy to produce. This step keeps costs low while meeting your performance goals.

Here is a simple table to help you compare cost and performance factors:

| Factor | Cost Impact | Performance Impact |

|---|---|---|

| Material Selection | High for alloys | High resistance, long life |

| Design Complexity | Higher for custom | Better efficiency |

| Manufacturing Ease | Lower for standard | May limit optimization |

| Maintenance Frequency | Lower for robust | Higher reliability |

You should ask yourself these questions:

What is my budget for tower internals?

How important is efficiency for my process?

Can I accept higher upfront costs for lower long-term expenses?

Will my process benefit from advanced materials or custom designs?

If you want expert help, you can reach out to Jiangsu VY Precision Machinery. Their team uses advanced CNC machining and design tools. They help you find solutions that fit your budget and your process needs. You get support from a company with years of experience in energy equipment.

Note: Smart selection of tower internals can save you money and boost your process. Take time to compare options and consult with specialists. You will see better results and fewer surprises down the road.

Choosing tower mechanical internals is not just about price. You need to look at how each choice affects your operation. When you balance cost and performance, you set your system up for long-term success.

Start by identifying what your process requires. You need to know your operating conditions, such as temperature, pressure, and the type of fluids in your system. Write down your main goals. These might include maximizing efficiency, reducing fouling, or making maintenance easier. Think about your capacity needs and how often you plan to clean the tower. If your process uses aggressive chemicals or high temperatures, you should note these details. This step helps you set clear priorities before you look at specific internals.

Tip: Make a simple list of your must-have features. This list will guide your decisions and help you stay focused.

Once you know your needs, you can create a shortlist of suitable tower internals. Look at the main types: trays, packings, grids, and supports. For each type, consider how well it matches your process. For example, if you expect fouling, you might prefer trays with open structures or special packings that resist buildup. If you need high efficiency, structured packings or advanced tray designs may work best.

You can use a table to compare options based on fouling severity and tray type:

| Fouling Severity | Recommended Tray Type | Key Considerations |

|---|---|---|

| Light fouling | Fixed valve trays or large-hole sieve trays | Cost-effective reliability |

| Moderate fouling | Fixed valve trays | Best balance of efficiency and fouling resistance |

| Severe fouling/polymerization | Dual flow trays or grid packing | Maximum reliability despite efficiency penalties |

This table helps you match your process challenges to the right internal design. You can also consider material options, such as stainless steel or advanced polymers, if your process involves harsh chemicals.

Every choice comes with trade-offs. You need to weigh the benefits and drawbacks of each internal. For example, some internals offer high efficiency but may cost more or require more maintenance. Others may resist fouling but have a lower separation performance. Think about your budget, your maintenance schedule, and your long-term goals.

Ask yourself these questions:

Will this internal reduce downtime?

Does it fit my budget and maintenance plan?

Can it handle my process conditions for many years?

Note: If you feel unsure, you can always consult with specialists. Jiangsu VY Precision Machinery offers expert advice and custom solutions. Their team can help you balance cost, performance, and reliability. Visit Jiangsu VY Precision Machinery for more information.

By following these steps, you can build a strong foundation for selecting the best tower mechanical internals for your process.

You can make better decisions when you consult with experts. Tower mechanical internals play a critical role in your process, so you should not rely only on general guidelines. Specialists help you avoid costly mistakes and find solutions that fit your unique needs.

Jiangsu VY Precision Machinery Co.,Ltd. stands out as a trusted partner in this field. The company operates from the Honglan Industrial Concentration Area in Lishui District, Nanjing, a city known for its rich history. Their factory covers 35,000 square meters, with 28,000 square meters of floorage. Since 2009, Jiangsu VY Precision Machinery has built a strong reputation for precision and reliability. You benefit from their complete set of imported numerical control cutting, sheet metal processing, welding, and machining equipment. These advanced tools give them large-scale CNC machining capabilities for metal structures.

You should know that Jiangsu VY Precision Machinery focuses on the design, manufacturing, and services of energy equipment. Their team understands the challenges you face in selecting tower internals. They offer tailored solutions that match your process requirements. You get support from professionals who know how to optimize efficiency, resist fouling, and simplify maintenance.

Tip: When you work with experts, you save time and reduce risk. You get access to the latest technology and proven designs.

Here is how you can benefit from expert consultation:

Personalized Recommendations: Experts analyze your process data and suggest internals that fit your goals.

Material Selection Guidance: You receive advice on the best materials for your operating conditions.

Design Optimization: Specialists help you balance cost, performance, and maintenance needs.

After-Sales Support: You get ongoing help with installation, inspection, and upgrades.

| Benefit of Consulting Experts | Description |

|---|---|

| Process Analysis | Experts review your data for accurate selection |

| Custom Design | Solutions tailored to your specific requirements |

| Reliable Manufacturing | Precision equipment ensures consistent quality |

| Technical Support | Assistance with troubleshooting and improvements |

You can contact Jiangsu VY Precision Machinery for expert advice and custom solutions. Visit their official website at https://www.jsvypm.com/ to start your consultation. You will find a team ready to help you achieve reliable and efficient tower operation.

Note: Expert consultation gives you confidence in your choices. You avoid common mistakes and set your process up for long-term success.

When you select tower mechanical internals, you want to avoid common mistakes that can lead to costly problems. Paying attention to these areas helps you keep your system running smoothly and efficiently.

Fouling happens when unwanted materials build up inside your tower. If you ignore fouling potential, you risk serious issues over time. Many operators underestimate how quickly fouling can affect performance. You should always consider the type of fluids in your process and how likely they are to cause deposits.

Here are some problems you may face if you overlook fouling:

Reduced Efficiency: Fouling can lower your tower’s ability to transfer heat or separate fluids. Your system will not work as well, and you may see drops in production.

Increased Mechanical Strain: Pumps and fans must work harder to move fluids through blocked paths. This extra effort can cause more breakdowns and raise your energy bills.

Potential Equipment Failure: If you let fouling go unchecked, it can damage your equipment. In some cases, you may face safety risks or need to replace parts sooner than expected.

Tip: Regular inspection and cleaning help you spot fouling early. You can also choose internals designed to resist buildup. For expert advice on fouling-resistant designs, consider consulting Jiangsu VY Precision Machinery.

Maintenance is not just a routine task. It keeps your tower internals working at their best. If you ignore maintenance needs, you may face unexpected shutdowns or expensive repairs. You should select internals that allow easy access for cleaning and inspection. Think about how often you will need to service your equipment and plan for it from the start.

A good maintenance plan includes:

Scheduled inspections

Easy-to-remove components

Clear access points for cleaning

When you make maintenance a priority, you extend the life of your tower and avoid sudden failures.

Choosing the wrong capacity for your tower internals can cause big problems. If you pick internals that are too small, your system may not handle peak loads. This can lead to bottlenecks, poor separation, or even system shutdowns. If you choose internals that are too large, you may waste energy and money.

You should always match your internals to your actual process needs. Review your flow rates, temperature, and pressure before making a decision. If you are unsure, reach out to specialists who can help you size your equipment correctly.

Note: Jiangsu VY Precision Machinery offers custom solutions to help you avoid these mistakes. Their team can guide you through the selection process and ensure your tower meets your performance goals.

By staying alert to these common mistakes, you protect your investment and keep your operation running smoothly.

You can select the best tower mechanical internals by following a clear process. Start with your process needs, then match internals to operating conditions, efficiency, and maintenance. Use the checklist to avoid common mistakes. Precision matters at every step. The table below highlights key aspects for alignment:

| Key Aspect | Description |

|---|---|

| Pre-Alignment Checks | Confirm foundation and minimize pipe strain |

| Alignment Methods | Use precise techniques for best results |

| Thermal Growth Compensation | Consider temperature effects on alignment |

| Final Verification | Recheck and document all alignment data |

| Post-Alignment Steps | Monitor and adjust under real operating conditions |

For expert support, consult Jiangsu VY Precision Machinery. Their team helps you achieve reliable and efficient tower operation.

Tower mechanical internals are parts inside process towers. You use them to support separation, distribution, and flow of fluids. Common examples include trays, packings, grids, and distributors.

You should consider your process needs, such as temperature, pressure, and fouling risk. Review your goals for efficiency and maintenance.

Material selection affects corrosion resistance and lifespan. You need to match materials to your process fluids and temperatures. Stainless steel and advanced polymers work well for harsh conditions.

You should inspect tower internals at least once a year. Regular checks help you find fouling, corrosion, or damage early. This keeps your system running smoothly.

Yes, you can upgrade tower internals to improve efficiency or handle new process needs. You should consult specialists for the best retrofit options.

Fouling often comes from solids, sticky fluids, or chemical reactions. You can reduce fouling by choosing the right internals and cleaning regularly.

You can get custom tower internals from Jiangsu VY Precision Machinery. Their team offers design, manufacturing, and support for your process.

Yes, tower internals affect energy use. Lower pressure drop designs help you save energy and reduce costs. Choose efficient internals for better performance.